OUR TECHNOLOGY WILL HELP YOU WITH

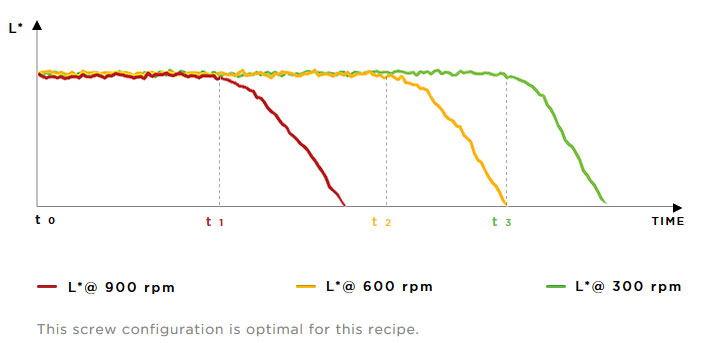

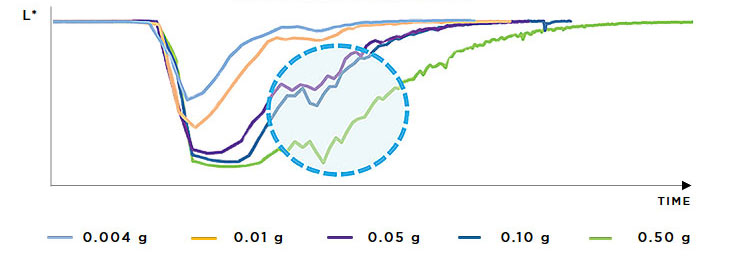

- Identification of optimal speed

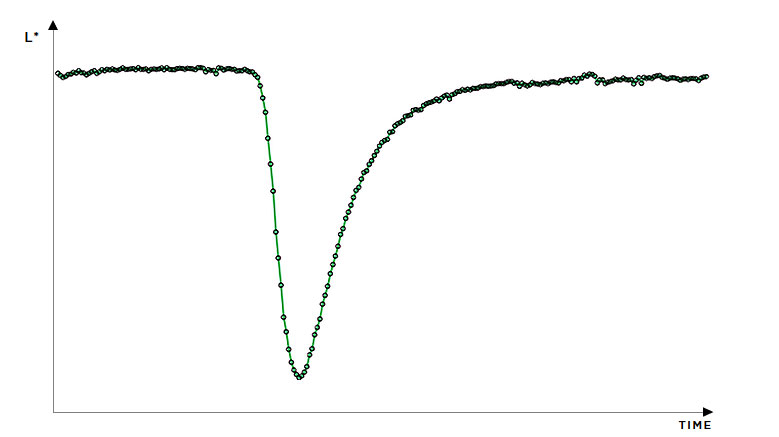

- Determination of optimal dispersion and homogeneity

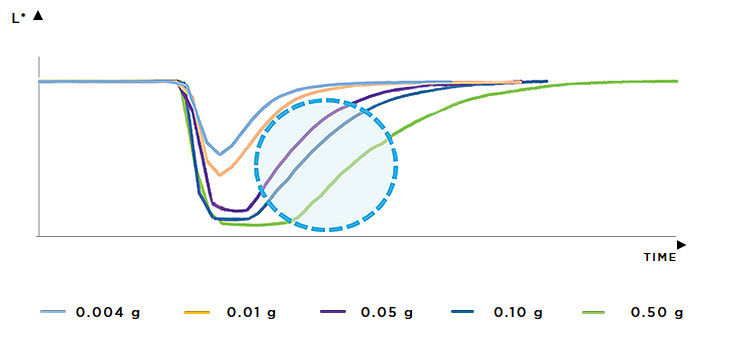

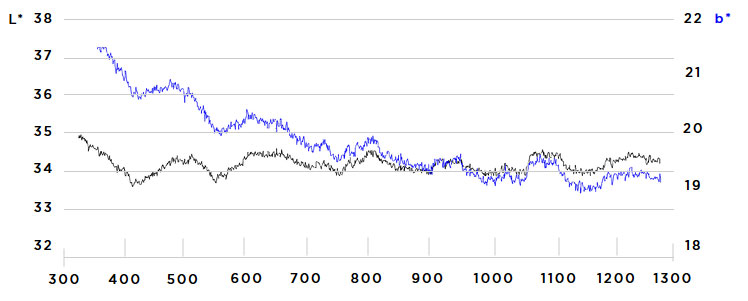

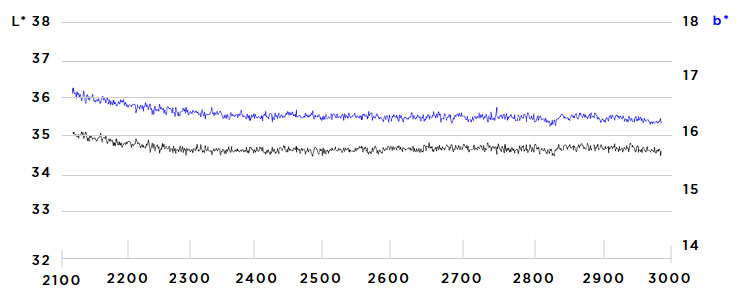

- Detection of dosage elevations – even very small elevations are detected

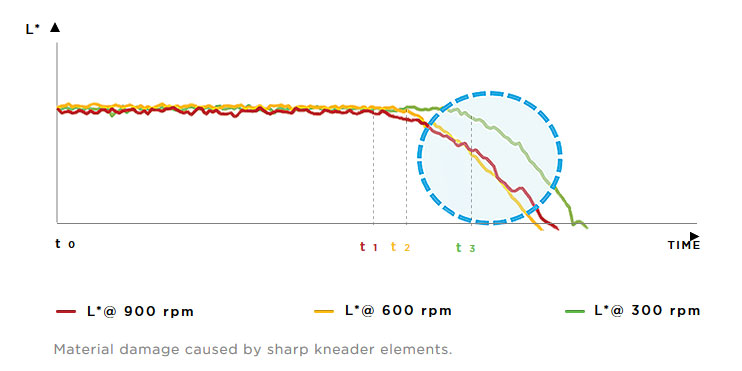

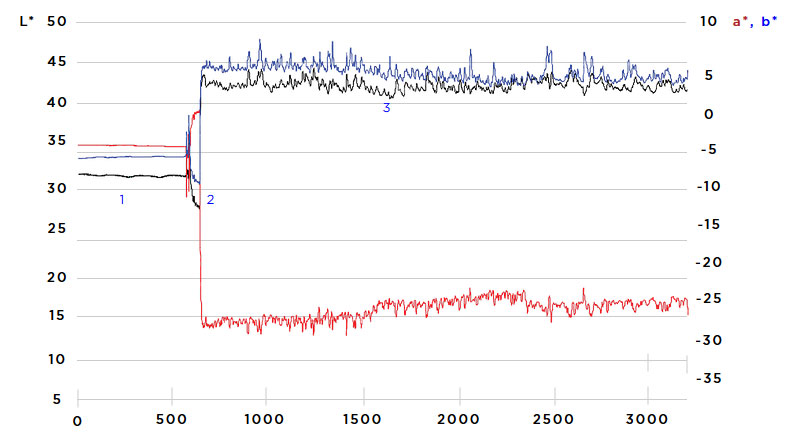

- Identification of off-spec batches (waste and contamination)